JANUARY - FEBRUARY 2007

The first half of January was warm. One day it hit 70 degrees, and I spent the day outside in a T-shirt.

Then the thermometer plunged into single digits, and I just could not drag myself out to a 24 degree garage.

It takes slightly longer than forever for the kerosene heater to warm up the garage. The garage has no

insulation and leaks air like a sieve, so once the heater is turned off, you can literally see the needle on

the thermometer moving downward.

I did get the grille assembly bolted together for a trail fit. It didn't fit. I loosened up the

parts, slipped the assembly between the fenders and tightened up the bolts. That worked. I then

disassembled it so that I could mount the stainless trim on the grille. After pounding it out, that is.

Fixing the stainless trim probably is a job best left to a professional, but being naive and

under the delusion that I could actually do this myself, I decided to give it a shot. I got the billions

of small dents and dings pounded and sanded out. The places where the trim was really messed

up are improved, but still need a little work. I went to Eastwood and bought an arbor and their

stainless buffing kit that consisted of the proper wheels and compounds. I borrowed the motor

from my diamond saw (every REAL geologist has a diamond saw in their garage for cutting up cores

and rock samples), attached the arbor and the first wheel, and clamped the assembly to an old

wooden bar stool I happened to have lying around (see picture to right. Also note my new classy

garage decor). The bar stool isn't great, but it is surprisingly sturdy, and it

the closest thing I have to a tool stand. I did the first wheel and compound and that didn't look

too bad. I still have the second and third one to go...

MARCH - APRIL 2007

I finished polishing up the stainless grill trim. You won't mistake it for something that just left Henry's

factory, but it doesn't look too bad for something I did in my garage. I slipped the grille assembly

in between the fenders and

tightened everything up. Sounded like a good plan, but it is very difficult to get at the bolts behind the grille

once it is on the front of the truck. My 3 foot socket extension came in handy. Yes, I finally found a use for

that thing. After tightening it up, the trim was no longer flush with the grille. I am not sure what went wrong

there, but it will have to come apart again.

Next came the grille sides. At the fender they are held on with 3 clips and two bolts with wing nuts. In my

collection of such hardware from 3 trucks, I managed to have exactly 6 clips, two studs, and one wing nut.

I sandblasted and painted the clips. A carriage bolt that fits into it, holds the clip to

the fender. I had to replace most of the carriage bolts as the threads were corroded beyond repair on

the originals. The stud and wing nut assembly is ingenious. The stud has a fat part in the middle. It is

inserted into the fender from inside the engine compartment and bolted on from inside the wheel well.

There is a slot in the hood side that slides over the stud, and the hood side is secured with the wing nut.

That means you can remove the hood side easily without having to remove the wheel to get at the nut behind it.

Since they do not reproduce these pieces of hardware, I had to make my own. I cut the head off the bolt of a

suitable length and repaired the threads where I made the cut. I welded a washer to the center of the

newly created stud and then ground it down to a size resembling the original. It worked out great. However,

the hood sides and the grille don't line up perfectly. After I attach the hood, I will loosen everything

in the front and jockey it around so all the sheet metal lines up.

I did about a bazillion other little things. I mounted the hood hinges and hood prop, installed the

wiper system (but did not test it yet), drilled the broken screws out of the windshield frame and tapped the holes,

repaired the parking light/turn signal assembly and mounted the

bulb holders in them. I put the guts in the headlight buckets. I have at least 8 headlights and managed

to come up with only 2 sealed beam conversion innards that were identical. The ones that came with

the truck were different! I painted and assembled them--

no easy feat considering what a corroded mess they were (especially the screws). I attempted to put

the glass in the windshield frame, but gave up before I broke it.

I decided to tackle fixing the doors, a chore I have been putting off for a very long time. The door bottoms were pretty rusted out, and there were rust holes in the front of the doors at the bottom. Fixing the doors seemed like a complicated job, so I put it off as long as possible. For once, procrastination paid off. I waited so long that they started producing replacement door bottoms.

I picked up a pair of newly stamped inner door bottoms from Northern Classic Trucks (P/N 3847IDB).

I cut the rusted bottoms off, trimmed the replacement metal to fit, and welded it in. I also cut out the parts of the door skins that were full of holes. I made patches out of some sheet metal that was laying around and welded them in.

Next followed the usual process of hammering, bondo, sanding, epoxy primer, high build primer, sanding through the primer to bare metal, more primer, and more sanding. After the final sanding with 600 grit paper, I washed the doors and shot the top coat. Something went right! There were no sags, runs, or major problems. No insects swimming in my fresh paint. The orange peel was minimal. I hope this happens again.

JULY - AUGUST 2007

I think I went backwards this summer. Sometimes I feel like that Greek guy, Sisyphus, who kept pushing

the boulder up the hill but never reached the top. Actually, this summer was more like one step forward, two steps back.

I put the hood on, but the hinges were not aligned correctly. As a result, the hood bound against the cowl and

chipped paint off both. It did that a few times until I got everything adjusted. What I didn't notice was

that my hood buckled a bit at one spot on the back end where it was binding.

Not I have a hood with chipped paint and a dent. I'll

work on that one later.

While the hood was on, I decided to get the latching mechanism lined up and also to install a hood catch with a cable

release in the cab. I got those parts from some import pickup in the junkyard. After hours of fussing I could get

one, but not the other to work. I decided to forego the stock latch and stick with the cable release latch, so

I removed the stock latch. Then I got to thinking that it would not be good if the catch accidentally released

while going down the highway and the hood flew open, so I put the stock catch back on. I still need to get the

release mechanism working. I'll work on that one later.

Since the hood was on, I put the hood sides on to see how everything would look. ARRUGH. There was like a 2-inch

gap between the hood and hood sides. I removed them, and loosened up all the fender and grille bolts and

tried to move everything upwards. I tightened all the bolts, put the hood sides back on, and noted only a

minor improvement. I took the hood sides and the grille assembly off. I'll work on that one later.

I got the glass in the windshield and all of the windshield pieces put together. That was not an easy task.

I wrapped the edges of the glass in rubber glass setting tape. I coated everything with soapy water and gently pounded

in the glass. Next, I attempted to put the rubber gasket around the outside of the windshield frame, but

there was still some bits of old rubber stuck in the groove. I cleaned out the old rubber and got the new

gasket installed. Again, not an east task getting the rubber in the grove. I set the windshield in the cab,

and it was not flush! There were big gaps between the cab and the windshield assembly on

both sides. I pulled the frame apart and took the glass back out. I'll work on that one later.

Since the grille was off again, I decided to install the finished headlight stands and

run the wires to the stands and headlights. When I finished the wiring last winter, I left all of the wires dangling

out the front. They were all tested, they all worked, and they were all labeled. The headlight stands are from the

1940-41 big trucks. They are identical to the 38-39 stands except that they have a built in parking light. I got the

stands bolted on and the wires cut to length and spliced in. I also ran the headlight wires to where they should

be as well as the wires for the fog lights. After everything was hooked up, I inserted the bulbs, turned on the

ignition, and tested my new installation. One parking light came on, and the turn signals did not work. I guess

I will have to rip out all of the wiring and trace every wire to see where things went wrong.

I'll work on that one later.

Just call me Sisyphus.

SEPTEMBER - OCTOBER 2007

My new goal is to be in December where I was in April. Lofty, huh? Taking one thing at a time...

I figured out the hood alignment problem. the radiator was set too far forward at the top. I purchased

stainless steel radiator support rods from Bob Drake and set the nuts as far back as they would go. Unfortunately,

it was not far enough. I removed the rods, cut an additional 2 inches of threads on each, and cut off 2 inches

of thread from the front of each one. When I reinstalled them, it moved the top of the radiator back 2 inches.

The hood fit much better, much of the gaps disappeared, and of course, the electric fan motor was well into the

serpentine belt. That meant moving the fan, which meant purchasing a new shroud, which meant draining the cooling system

and removing the radiator. I believe that there is a corollary to Murphy's Law that states "Before you can do something,

you have to do something else." Anyway, I bought a new shroud, positioned the fan so it would not be in the way

of the drive belt, cut a hole in the shroud, and remounted everything. One problem solved.

While I had the radiator off, I ripped out the wiring in the front. That turned out to be unnecessary

as I EVENTUALLY traced the problem to faulty plugs in the steering column. One that was fixed, the lights

in the front worked as they were supposed to. On the bright side, I did a much neater job of bundling and

routing wires the second time. A second problem solved.

I put the grille back on and realigned the front sheet metal. It fit somewhat better but the fit is still

not spectacular. I guess I will just live with it. Chant the mantra: It's a driver. It's a driver.

Once the

hood fit right, I got

the hood catch with a cable release in the cab installed and working. That problem turned out to the nut holding

the the plunger looking thingy (whatever its called) to the underside of the hood. The nut, which was a

standard size nut, was too thick.

I removed it and cut about 2/3 of it away with a cutoff wheel and then smoothed it out on the grinding wheel.

I replaced the nut, got everything lined up, and it worked perfectly! Another problem solved.

And in the midst of doing all of this, I had to repair my daughter's car. She had a run-in with a very, very

large oak tree, and the tree won. It took out the right front, right fender, and right door. It also did a bunch

of minor damage that I am not going to worry about. I replaced the air bag, air bag sensors, headlight assembly,

side marker light, bent the remains of the fender off the tire, and removed the plastic inner fender that was wrapped

around the axle. At that point it was drivable but was not a pretty sight. Several trips to the junkyard produced

a header panel, fender, and door, none of which were the right color. It seems that every car in the junkyards

had a bashed in door and fender on the right side, so I picked ones with the least amount of body damage.

After a little bondo and a little primer, I painted the parts to match the rest of the car. Off with the old

and on with the new, and her car looks almost as good as new.

NOVEMBER - DECEMBER 2007

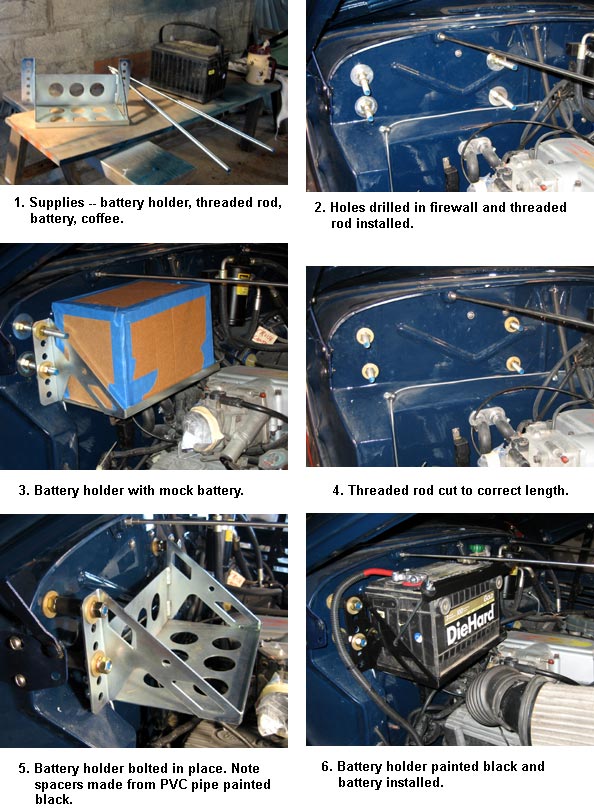

My BIG accomplishment was the installation of the battery under the hood. I was really, really, really

hoping it would fit there, and I would not have to put it under the seat or the bed or somewhere

inconvenient. I took some pictures of the installation.

First, I searched the Internet for a suitable battery holder that might actually fit under the

hood. P/N 91666007 from

Speedway Motors

looked like it would probably fit (a real solid reason), so I ordered it.

Next I needed a battery that would fit in the holder. Battery sizes are standardized by the

BCI (Battery Council International) and BCI sizes are

conveniently listed on the

Golden Gate Lotus Club website. I determined that a

Group 34 or 78 battery would be ideal. I looked around and found a

Diehard Gold Group 34/78 battery with 900 cold cranking amps in the Austin Healey, so it came

out of the Healy. I don't really need such a big battery in the Healy, but when a little battery

with 400 CCA and a somewhat larger battery with 900 CCA that will fit is the same

price, I go for the bigger battery.

I made a cardboard mock battery the same size as the real one and fiddled with the mock

battery in the holder under the hood to find a place it would fit. God must have been smiling down

on me that day because I found a place where it would clear the hood, the hood side panel,

and the throttle body (by a hair). I marked the holes on the firewall, and headed to the hardware

store for some 1/2 inch threaded rod. I picked 1/2 inch because that was the size of the mounting

holes in the battery holder, and a rod that size would provide good support for a 44 pound battery.

I also bought two rods because I wanted the nice finished ends protruding under the hood, and not the

sawed off jagged ends.

I purposely cut the treaded rod too long and bolted it to the firewall through the holes

I drilled. I slid the battery holder onto the threaded rod and bolted it on. I marked the rod

so I would know how much to trim off and also measures the exposed rod between the firewall and the

battery holder. I trimmed the rod to the proper length and also cut some PVC plastic water pipe (which I painted

black) to cover the exposed threads. I put everything together to make sure it would fit, took it apart,

and painted the holder black. After the paint was dry, I reassembled everything and installed the battery.

It was a tight fit to slip the battery in, and I had to bend the radiator support rod upward a little to

get it to clear. Once it was in, it cleared everything! I went to attach the hold down bar and

uh oh, the hold down rods supplied with the holder were too short. A trip to the auto parts store

netted a pair of cheesey hold down rods for $3. I cut off the excess thread and bent the hooks on the bottom

a little, and completed the installation.

I put the glass back in the windshield frame. It was the third, maybe fourth time. I am getting to be quite an expert at

it. I put the rubber gasket back around the frame and screwed the upper and lower hinges to the frame. I got the

crank-out mechanism working, but there is still a considerable (and unacceptable) gap between the windshield frame

and the cab. It will have to come apart again, but i decided to get the wipers hooked up and working in the

meantime. I just got started on that.